Technical proficiency alone is insufficient to succeed in the rapidly changing electronics sector. The most successful engineers develop daily routines that maintain flexibility, effectiveness, and accuracy. Your routines can have a big impact on your results, whether you’re working with a PCB supplier in Singapore, developing intricate circuits, or improving prototypes.

Here are seven habits that distinguish highly successful electronics engineers from the rest—and how you can adopt them to elevate your work.

1. They Prioritise Early Prototyping

Rather than waiting until the end of a design cycle, high-performing engineers prototype early and often. This habit allows them to identify design flaws and functional limitations before they become expensive problems.

With access to fast prototype PCB assembly services, they iterate quickly, validate performance in real-world conditions, and confidently move toward production. Early prototyping reduces uncertainty, fosters innovation, and leads to better design decisions.

2. They Maintain Precise Documentation

Successful engineers never treat documentation as an afterthought. From schematic diagrams to fabrication notes, they keep detailed and organised records of every design change and system modification.

This habit prevents confusion during handoffs, facilitates team collaboration, and streamlines communication with PCB manufacturing partners. In the context of PCB manufacturing in Singapore, clean documentation reduces the risk of errors during fabrication and shortens lead times.

3. They Stay Current with Industry Trends

Technology in electronics manufacturing moves quickly. Engineers who stay ahead regularly read industry publications, attend webinars, and review product datasheets. They understand emerging standards, such as those involving material tolerances or new enclosure specifications.

Staying informed allows them to recommend cutting-edge solutions—like using a custom PCB enclosure for optimal thermal performance or modular upgrades. This habit ensures they remain valuable in an ever-changing market.

4. They Collaborate with Suppliers Early

Rather than sending off design files at the last minute, successful engineers engage with their PCB supplier in Singapore early in the process. They seek insights into manufacturability, material selection, and cost optimisation well before finalising layouts.

This proactive communication avoids costly rework, enhances fabrication quality, and ensures the final product meets both performance and budget expectations. Early collaboration builds stronger partnerships and leads to smoother project execution.

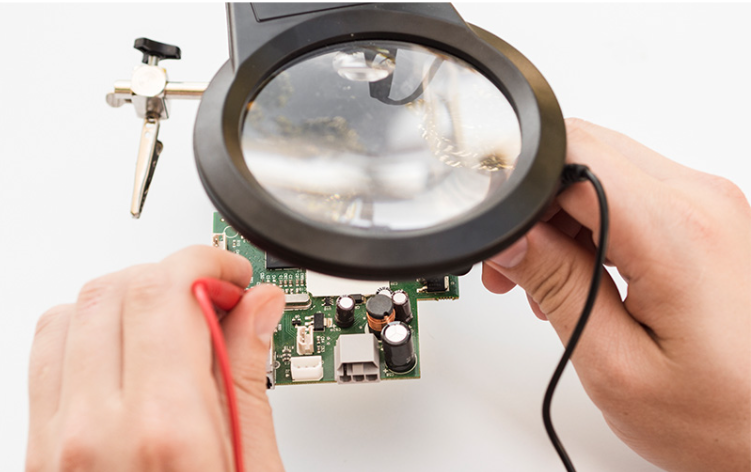

5. They Build for Testability

Engineers who consistently deliver strong results design their boards with testability in mind. They ensure there’s space for test points, that power lines can be isolated, and that the firmware allows diagnostics.

Whether during in-house debugging or post-manufacture testing, these features help pinpoint faults quickly. It’s a habit that reflects foresight and a deep understanding of the full product lifecycle—from concept through PCB manufacturing and assembly.

6. They Embrace Modular Thinking

Rather than designing from scratch for every project, top engineers adopt modular thinking. They reuse proven circuits, standardise component footprints, and separate core functions from peripheral features.

This method accelerates development timelines and simplifies troubleshooting. It also enhances compatibility when working with external services like custom PCB enclosure fabrication or prototype PCB assembly services, where uniformity can improve production accuracy.

7. They Review Before Final Release

Before locking in a final design, high-performing engineers always conduct a structured review. They check routing, clearances, power distribution, and bill of materials alignment. They don’t rely solely on automated checks—peer reviews and visual inspections are integral.

This habit drastically reduces the chance of production delays and post-fabrication issues. In high-stakes environments such as PCB manufacturing in Singapore, a final review can mean the difference between seamless delivery and an expensive delay.

Better Habits Build Better Engineers

Excellence in electronics engineering doesn’t arise by chance. It’s shaped by the habits that engineers practise every day—habits rooted in communication, foresight, and continuous learning. By adopting these seven habits, engineers improve their collaboration with manufacturers, minimise design risks, and increase the reliability of their products.

From working with a trusted PCB supplier in Singapore to integrating custom PCB enclosure features and leveraging fast prototype PCB assembly services, the most successful engineers know how to maximise their environment.

Ready to streamline your workflow and raise the bar on quality? Contact MPN Tech today to power your next project with reliable PCB manufacturing support.